|

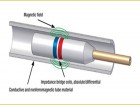

- Eddy current coil generates primary magnetic field

- Primary magnetic field induces eddy currents in the material

- Eddy currents generate secondary magnetic field in the opposite direction

- Coil impedance changes, as a result

- Impedance change is measured, analyzed and correlated with defect dimensions

Advantages of ECT

- ECT can be used to inspect Non-Ferrous Tubes ( eg. SA249-TP304L, SA249-TP316, Brass, Titanium, Inconel, Monel, Cupro-Nikel, etc. )

- Eddy Current testing is suitable for detection, sizing and quantified, affordable and quick method of inspection.

- Can detect ID / OD pitting, fretting, stress cracks, localized corrosion

- Fast method inspection. Able to inspect 700 tubes with 6m length per day, subjected to tubes conditions.

- It’s possible to detect and quantify defects under support plates